High-performance, high-power servo motor and CNC system control make tapping of small aperture and blind hole more accurate and higher precision. The second origin can be set arbitrarily, and the processing efficiency is greatly improved. The maximum speed is 3,370 rpm. High-speed machining ensures high-precision thread machining of JIS class 2 (6H).

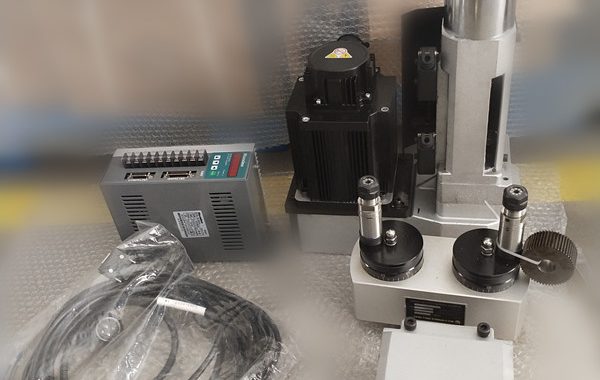

It can also be combined with multiple spindle head.This is a photo before the product packaging for your reference.

Product performance and features:

1. Because the tool feed and rotation are synchronized, very thin or soft materials can be processed efficiently.

2. The diameter, pitch and stroke of the machined thread can be easily adjusted.

3. Connect with PLC to realize data control, which can realize fast stroke fast feed, slow tapping, slow return wire, and quick return.

4. With long stroke and many types of accessories, it is convenient to replace the single-axis tapping head with multi-axis tapping head, which can meet the needs of users in small batches and large batches.

We can provide suitable models according to the tapping requirements of customers.